What We Should Know about Half Cell Solar Panel?

Panel trends have a way of quickly becoming mainstream. IHS Markit predicted that passivated emitter rear cells (PERC) technology would go from a blip in the market in 2014 to mainstream by 2020—a prediction

confirmed by anyone looking at panel models released this year. PERC is here to stay.

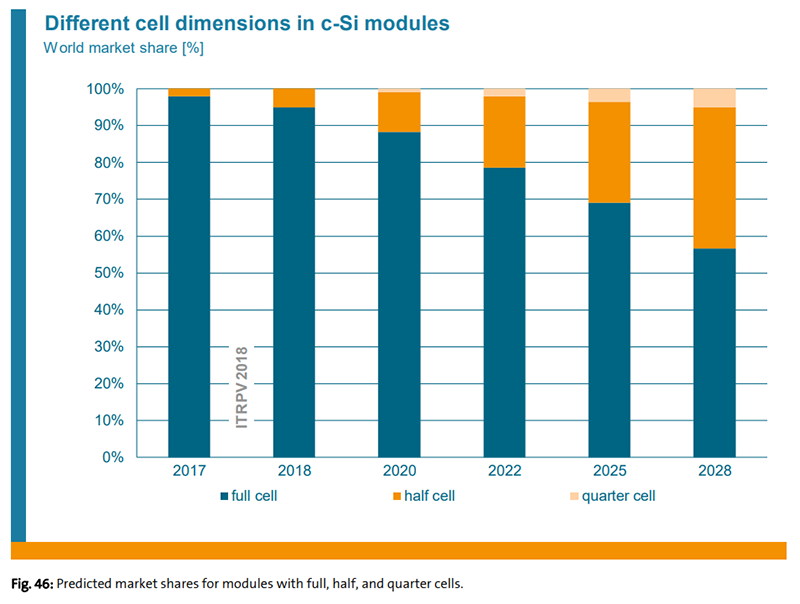

The next technology on that mainstream path is half-cell designs. The ninth edition of the International Technology Roadmap for Photovoltaic (ITRPV) predicts the market share of half cells will grow from 5% in

2018 to nearly 40% in 2028.

Half-cell modules have solar cells that are cut in half, which improves the module’s performance and

durability. Traditional 60- and 72-cell panels will have 120 and 144 half-cut cells, respectively. When solar cells

are halved, their current is also halved, so resistive losses are lowered and the cells can produce a little more

power. Smaller cells experience reduced mechanical stresses, so there is a decreased opportunity for

cracking. Half-cell modules have higher output ratings and are more reliable than traditional panels.

“When considering a solar installation, the idea of ‘more’ is at the forefront—produce more energy, save (or

earn) more money and do more good for the environment,” said Cemil Seber, VP of global marketing and

product management for module manufacturer REC.

“In the case of rooftops where there is a limited amount of space available, using solar panels with half-cut

cell technology can help.”

REC is a half-cell pioneer, first introducing the design in 2014. The company’s TwinPeak half-cell module series

effectively turns each panel into two twin panels. Since the cells are smaller, inter-cell spacing doesn’t have

to be as wide and they can be placed closer together. This allows REC to separate the panel into two.

Independent upper and lower module halves lead to improved shading response. If the bottom half of a

module is shaded, the top half will still perform.

The manufacturers included Hetechsolar have started half-cell designs in the monocrystalline class. LONGi

Solar recently exceeded 360 W in testing with its 120-cell half-cut monocrystalline PERC module.

Hanwha Q CELLS received the Intersolar Award 2018

Photovoltaics category for its Q.PEAK DUO-G5 solar module—a 120-half-cell, six-busbar monocrystalline

module. The Hanwha module uses round wires instead of flat ribbons for busbars to reduce shading on the

cells. Hanwha also has half-cut designs for the 72-cell market, although in polycrystalline. Its Q. PLUS DUO L-

G5.2 is a polycrystalline half-cell module with a maximum output of 370 W.

Hanwha Q half cell

Half-cut cells (Photo from Hanwha Q CELLS SPI 2017 booth)

Since half-cell designs are the hottest trend right now, a manufacturer just has to update a few things on its

lines to keep up.

The two challenges with switching full-cell manufacturing to half-cell designs is the cell cutting and the

stringing process.

Since half-cells are usually PERC cells to begin with, the cell itself is quite fragile. Laser-cutting the cell down

the middle without cracking it is a delicate process. Half-cells often use four or more busbars. Stringing these

very narrow connection strips across a smaller footprint requires the use of precise equipment. Junction

boxes are also different on half-cell modules.

Most brands use multiple, smaller junction boxes so each module half can function as its own. Otherwise, half-

cell module assembly is like full-cell production.

Since half-cell modules produce more power and are more efficient and reliable than their full-cell

counterparts, their use can lead to time and money savings for the installer.

“By delivering more power per square meter, fewer panels are required to generate the same power,” Seber

said. “This means quicker installation times and the need for fewer components such as clamps and racks—all

of which reduces the overall costs.”

Categories

latest blog

© Copyright: 2026 Sunetraco All Rights Reserved.

IPv6 network supported